Whether you're a startup, researcher, or industry team

We help you design, build, and refine ideas into working prototypes — without the usual barriers.

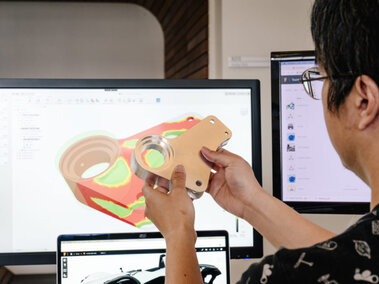

3D DESIGN & DEVELOPMENT

3D DESIGN & MODELING

We help turn your ideas, drawings, or physical parts into accurate and fabricable digital models. Whether you're prototyping a product, need something 3D printed, or need to make copies of a hard-to-replace item, our team can support each step of the process.

Capabilities include:

- CAD modeling (solid and surface)

- Product visualization, assembly animation, and rendering

- 3D scanning and reverse engineering

- STL repair and file cleanup

- Prototype design and iteration support

- 2D <-> 3D documentation generation

- Enclosure design

- DFM / DFA guidance

3D Design & Modeling

Examples:

Morrill Hall Specimen Scanning

NEED: Create digital models of fossil specimens for education and outreach

SOLUTION: 3D scanned bones and fossils using high-resolution metrology tools, then cleaned and prepped the files for 3D printing

RESULT: Morrill Hall staff can now print durable replicas to distribute to guests from far and wide

✔️ Digitized fragile, irreplaceable specimens

✔️ Streamlined repeat use — museum staff drop off, we handle the rest

✔️ Supported STEM education and outreach statewide

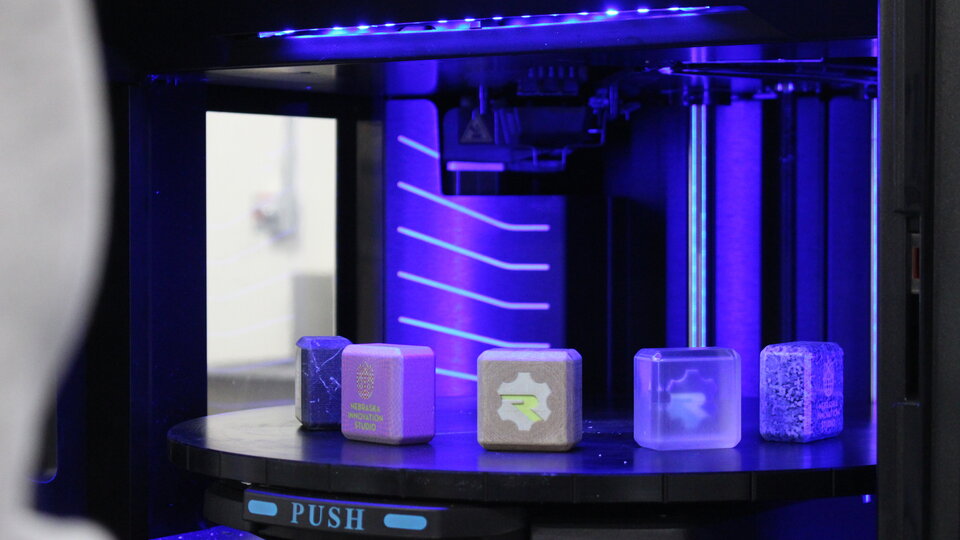

DIGITAL FABRICATION & MACHINING

We fabricate parts using NIS' extensive library of additive, subtractive, and hybrid tools. From single components to complex assemblies, we can produce fast, high-quality results in plastics, metals, and more.

Capabilities include:

- 3D printing (FDM, SLA, SLS, PolyJet, large-format)

- Small Volume Metal Casting

- CNC machining (mill, lathe)

- Sheet metal cutting and forming

- Plasma cutting, Fiber Laser cutting + marking + engraving + welding

- Small volume production

- Advanced welding, including MIG, TIG, Fiber Laser Welding/Cutting/Cleaning, and Robotic MIG

- Powder coating and finishing

- Assembly and fit-up

Examples:

Huge Savings in Large-Format FDM Printing

NEED: Large-format functional 3D parts for product validation

SOLUTION: 309 hours of F770 printing with custom file prep and weekend check-ins

RESULT: Delivered faster and cheaper than outsourcing — $3.7K vs. $11K market rate

✔️ 3D printed over 300 hours of large-format parts

✔️ Saved client 67% vs. commercial providers

✔️ Let client engineers focus on R&D, not operations

SYSTEMS PROTOTYPING

Some prototypes need a bit more — sensors, boards, motors, or integrated control. We offer support for projects with light electronics and electromechanical components.

Capabilities include:

- Embedded systems and microcontroller setup

- PCB layout and prototyping

- Sensor and actuator integration

- Functional test builds

- Electromechanical assembly and testing

- Mechatronics design

- Sensor integration

- System-level debugging and testing

Examples:

Cattle Kettle Distributed Monitoring Prototypes

NEED: Refine a rugged, cellular-connected monitor for livestock water tanks

SOLUTION: Supported multiple iterations of enclosure design, internal layout, and field-ready packaging; helped troubleshoot cellular communication issues and advised on manufacturability

RESULT: Advanced from early prototype to manufacturable design, ready for field pilots and investment conversations

✔️ Integrated electronics + mechanical systems

✔️ Iterated rapidly for usability and field conditions

✔️ Provided technical advising during incubator and grant phases

Digital Fabrication

Training & Workshops

Teach a man to fish, and you feed him for a day. We provide hands-on training for individuals and teams looking to learn prototyping tools, fabrication techniques, or equipment safety.

Offerings include:

- Tool certification and safety training

- CAD and 3D printing workshops

- Certificate-granting courses in Robotics, Drone pilotry, and Robotic Welding

- Fabrication and prototyping workshops

- Custom sessions for student groups, faculty labs, or external partners